Overview

| Type: | Wire Brush |

| Brush Material: | Steel wire |

| Product name: | Steel wire brush copper wire stainless steel knife brush small iron brush wood handle copper wire brush |

| Brush filament: |

wire,tamipico |

| Bristle: | Steel wire |

| Place of Origin: | Shanghai, China |

| Function: | Polishing/cleaning/deburring |

| Application: | polishing,deburring |

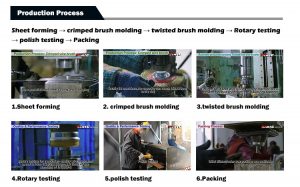

| Production technique: | Epoxy cast,spiralwound,staple-set,hand-drawn |

| MOQ:

|

10 pieces |

Supply Ability

6000 Piece/Pieces per Month Mounted Nylon Wire Brush Wheel

Packaging & Delivery

Packaging Details -opp bag/hard carton/plywood box

-other requirements per customer

Lead Time:

| Quantity(Pieces) | 1 – 51 | >51 |

| Est. Time(days) | 20 | To be negotiated |

Description:

80*35*6mm Mounted Nylon Wire Brush Wheel P120 P240 P600 Wood Furniture Grinding Flower Head Air Grinder Drill Rotary Tool work best at speeds allowing fairly deep penetration of the work piece into the brush filaments. Faster speeds do not typically work as well as slower speeds. 80*35*6mm Mounted Nylon Wire Brush Wheel P120 P240 P600 Wood Furniture Grinding Flower Head Air Grinder Drill Rotary Tool are made with plastic base and abrasive filament. Diamond abrasive nylon filament diameter available standard are 0.3mm, 0.45mm, 0.6mma and 0.8mm in and #240, #600, #800 and #2000. 80*35*6mm Mounted Nylon Wire Brush Wheel P120 P240 P600 Wood Furniture Grinding Flower Head Air Grinder Drill Rotary Tool work best at speeds allowing fairly deep penetration of the work piece into the brush filaments. Faster speeds do not typically work as well as slower speeds. ROTATIONAL DIRECTION On the initial pass of the Diamond Abrasive Nylon Filament Brushes for deburring and polishing, rotation should be in the opposite direction of the cutting tool that created the burr. Diamond Abrasive Nylon Filament Brushes for deburring and polishing should overlap edge of working piece by 1″ minimum. The ideal brush path is in the opposite direction of travel from the cutting tool that created the burr. The brush path should also be longer than the cutting tool path, to a point where the trailing edge of the brush is effective on the end of the part. Lastly, to maximize the amount of filament that is striking the part, the center line of the brush should be offset from the center of the part. The abrasive action occurs when the sides of the brush filament slide across the part surface or edge of the part. When the correct balance between speed (RPM), penetration, dwell time and abrasive grit size are achieved, then optimum life and cut can be obtained. The characteristic of diamond abrasive nylon bristle Diamond is a hard ceramic with low thermal expansion. This fine grain abrasive filament is well-suited for fine finishing and cleaning.

We promise

-100% QC inspection before shippment

-FULL REFUND in case of any bad quality or late delivery

-quality assurance contract signed

-confidential agreement signed

– small order welcomed

Q&A:

Q: What is the advantage of your products?

A: Stable quality, on-time delivery, competitive factory price, honest service.

Q: Are you trading company or manufacturer?

A: We are a factory with 21-years experience.

Q: Can you provide free samples? How long can I get sample product?

A: Yes. Normally 2-3 days for stock samples. 7-10 days for customized samples.

Q: Do you provide testing report?

A: Yes, we test as required and provide testing report.

Q: How long is your delivery time for bulk order?

A: Usually 15-25 days, it is different according to actual quantity.